By Mark Plummer MSc BEng

Stuart Wright Pte Ltd’s (SW) CEO, Colin Stuart, and Well Engineer, Mark Plummer recently completed a one-year project supporting the Department of Natural Resources Mines & Energy (DNRME) in Queensland, Brisbane to perform a Well Programme Assurance Design and Construction Review (WEPA DCR) for high risk and complex wells.

The objectives of the WEPA DCR were to understand, by observation, how operators are meeting the relevant statutory provisions in the legislation; including subsidiary mandatory safety requirements, the Queensland Code of Practice and recognised industry standards. Consistent with the Queensland government policy, the Inspectorate is collaborating with the industry to promote the safety and technical standards for petroleum and gas operations.

Following consultation and dialogue with industry, seven (7) Operators were selected as suitable candidates for the well programme assurance review. The programme was conducted in three stages as outlined in Figure 1 below.

Figure 1 – WEPA Design & Construction Review Process

WEPA Stage 1 – Understand with the petroleum operator, their well design protocols and standards, and agree specific well selection;

WEPA Stage 2 – Engage in well design and planning process of the selected well programmes; and finally; and

WEPA Stage 3 – Oversee well construction against the plan in the well execution stage. In particular to carry out well barrier monitoring and validation using SW’s proprietary Right Time Barrier Condition (RTBC) well barrier monitoring system.

Well Design Phase Review Methodology

Through discussion between the Regulator and each individual Operator, eight (8) suitable candidate wells were identified for the Well Programme Assurance review. Subsequently, a copy of Operator standards and well specific documents (e.g. Well Basis of Design, Drilling Programme, Drilling Fluids Programme, Cementing Programme, Casing and Tubing Design, Well Barrier Programme) were provided by the Operator for review by Well Inspectors.

The design phase review methodology was as follows:

- Tenure holders informed DNRME of the commencement of well design and provided relevant corporation documents/standards to DNRME.

- Inspector(s) from DNRME reviewed operator documents/standards and identified that they comply with mandatory regulatory requirements or noted any gaps.

- Inspector(s) from DNRME reviewed the well specific programme including ‘well basis of design’, ‘drilling fluid programme’, ‘casing & tubing design report’, ‘well barrier programme’ and ‘cementing programme’ to confirm if these documents were compliant with mandatory regulatory requirements and good industry practice.

- DNRME raised any clarifications arising from the standards and well design review with the Operator via a clarification register.

- DNRME provided a summary report containing any apparent non-conformance items for discussion with the Operator.

Well Construction Phase Review Methodology

Stuart Wright’s proprietary well barrier monitoring and validation system, RTBC, was used by DNRME to monitor drilling operations for selected wells. This exercise was the final stage for a given selected well, in DNRME’s WEPA DCR programme.

The system was used to assess each well for compliance, with their own standards and mandatory regulatory requirements. Specific barrier acceptance criteria were created in RTBC, which were extracted from Operator standards, the drilling programme and relevant legislation. Each barrier element during well construction was then assessed for reported validation, and assigned a traffic light colour (red, amber, green) rating depending on the result of the rating.

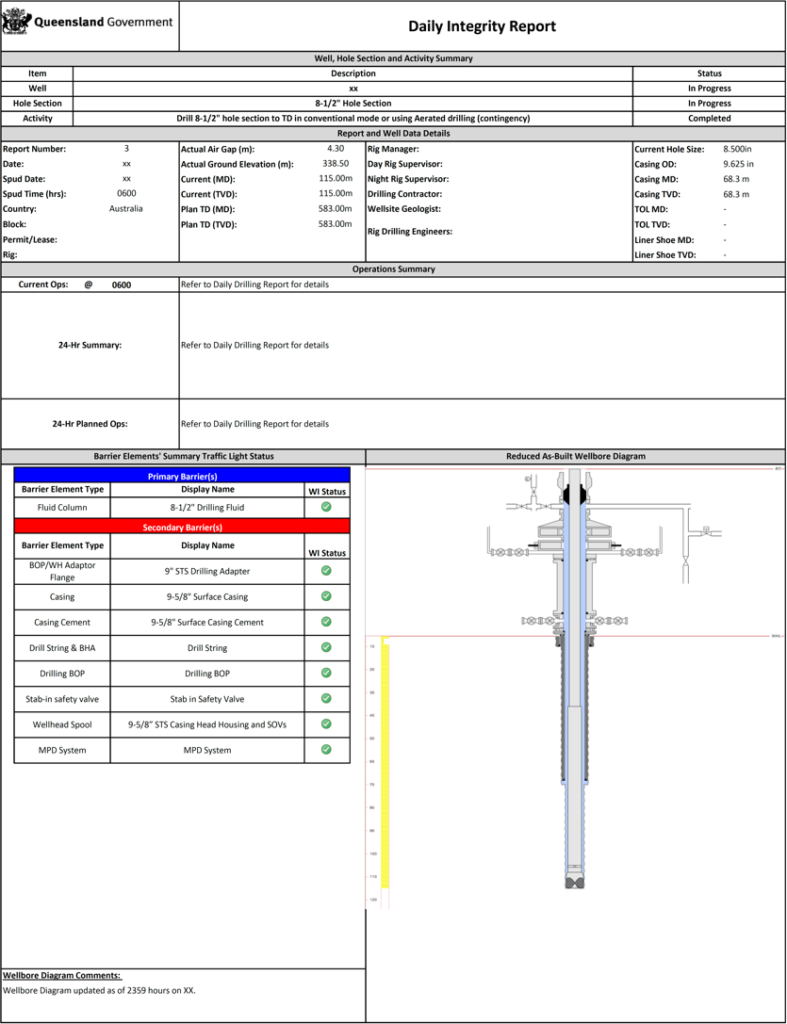

RTBC creates a Daily Integrity Report (DIR) capturing the barrier validation result.

The process of assessing compliance during well construction was as follows:

- DNRME set up a specific Barrier policy library for each Operator in RTBC

- DNRME set up a Well Barrier Plan based on the drilling programme, capturing all well construction activities and planned barrier validations

- DNRME received DDRs and other daily reports from the Operator from well spud until suspension/abandonment

- DNRME reviewed the operations stated in the Daily Drilling Reports (DDRs) and other daily reports and updated the barrier conditions and as-built diagrams in RTBC

- A Daily Integrity Report (DIR) was created for each day of operations for internal DNRME review before distributing to the Operator (see Figures 2A and 2B below). Any apparent gaps or discrepancies were discussed directly with the appointed Operator personnel

Figure 2A – Example Daily Integrity Report (Pg.1) – sent to Operator on a Daily Basis

Figure 2B – Example Daily Integrity Report (Pg.2) – sent to Operator on a Daily Basis

Key Findings

A range of useful findings arose from the WEPA study and, in particular, the use of RTBC to track barrier validation during well construction provided close monitoring and feedback which was beneficial to both the Regulator and Operator:

KF #1 – In general, the Operator standards compliance with mandatory regulatory requirements was good, but with individual exceptions which were fed back to Operators and improvement processes agreed.

KF #2 – Maintaining an overbalance margin to the bottom hole pressure (BHP) is a critical barrier during well construction. Operator standards for petroleum wells reviewed by DNRME could be further enhanced by stipulating a minimum overbalance to BHP requirement.

KF #3 – Several Operators did not achieve regulatory compliance with the minimum 70% standoff for casing centralisation in their well design. The primary reason cited for this non-compliance was that the centralisation modeling simulation called for large sections of the casing having 2 centralisers per joint to achieve the required 70% standoff and Operators opined that the risks associated with running this many centralisers outweighs the benefit.

KF #4 – During the WEPA study, DNRME noted that the Operator’s design and planning process was often completed very late and, in many cases, only a few days prior to well spud which has an impact on risk during the well construction phase.

KF #5 – 75% of the gas-producing petroleum wells reviewed during the WEPA study were designed with standard Buttress Thread Connections (BTC) or Long Thread Connections (LTC) in the production casing string, which is common practice, deemed to be adequate as reservoir pressures were less than 3,000 psi. For gas-producing petroleum wells, the selection of premium (gas-tight) connections would help to mitigate, over time, the risk of a leak path for hydrocarbon gas into the B-Annulus with associated consequences, though DNRME accepted that current industry standards support the common practice and the risk assessment approach currently used is valid.

KF #6 – The use of a barrier monitoring system demonstrated that Operators could not, in a limited number of cases, show compliance in all respects with their own standards and regulatory requirements during well construction given the conventions and format of the standard DDR reporting process. The Inspectorate had to review documents and data other than the DDR to complete the barrier validation picture.

KF #7 – The integrity reporting system used (RTBC) did give regulator and operator insight into escalating compliance risks. Furthermore, it allowed the Inspectorate to demonstrate in the captured database, a record that the operator is in compliance with regulation OR where they are not, it is transparent, and a flag raised.

KF #8 – The Daily Drilling Reports (DDR) focus is typically around performance and Occupational Health and Safety (OHS). However, no clear picture emerges in a typical DDR of an equal focus on well integrity and specifically loss of control risk.

Preliminary Conclusions of the WEPA Study

The findings and preliminary conclusions of the WEPA study were presented, on behalf of DNRME, by Colin Stuart at the Oil & Gas UK “Safety 30 – Piper Alpha Legacy: Securing a Safer Future” conference which was held in Aberdeen in June, 2018. A summary of the preliminary conclusions of the WEPA study is detailed below:

- There was some evidence of failure to follow approved plans during execution, particularly when problems developed. Management of Change (MOC) documents did not tell the complete picture.

- The use of a Daily Integrity system approach created transparency when deviations occurred, and forced better management response.

- The WEPA programme showed potential to reduce risk through better well integrity transparency. This could be achieved, as demonstrated, through the use of RTBC to properly identify Controls, assess that these have been Validated and record the Evidence of validation using a modern cloud-based data storage solution, which ensures data availability and instant retrieval and analysis.

- The WEPA process has important implications for Oil and Gas wells but also emerging Geothermal well projects where, due to the current absence of global standards, compliance challenges exist.

- The WEPA approach could be deployed across several international regulators to create a limited but global barrier validation best practice and potential failure databasefor well construction, including all critical component failures affecting well integrity.

This project summary has been approved by DNRME.